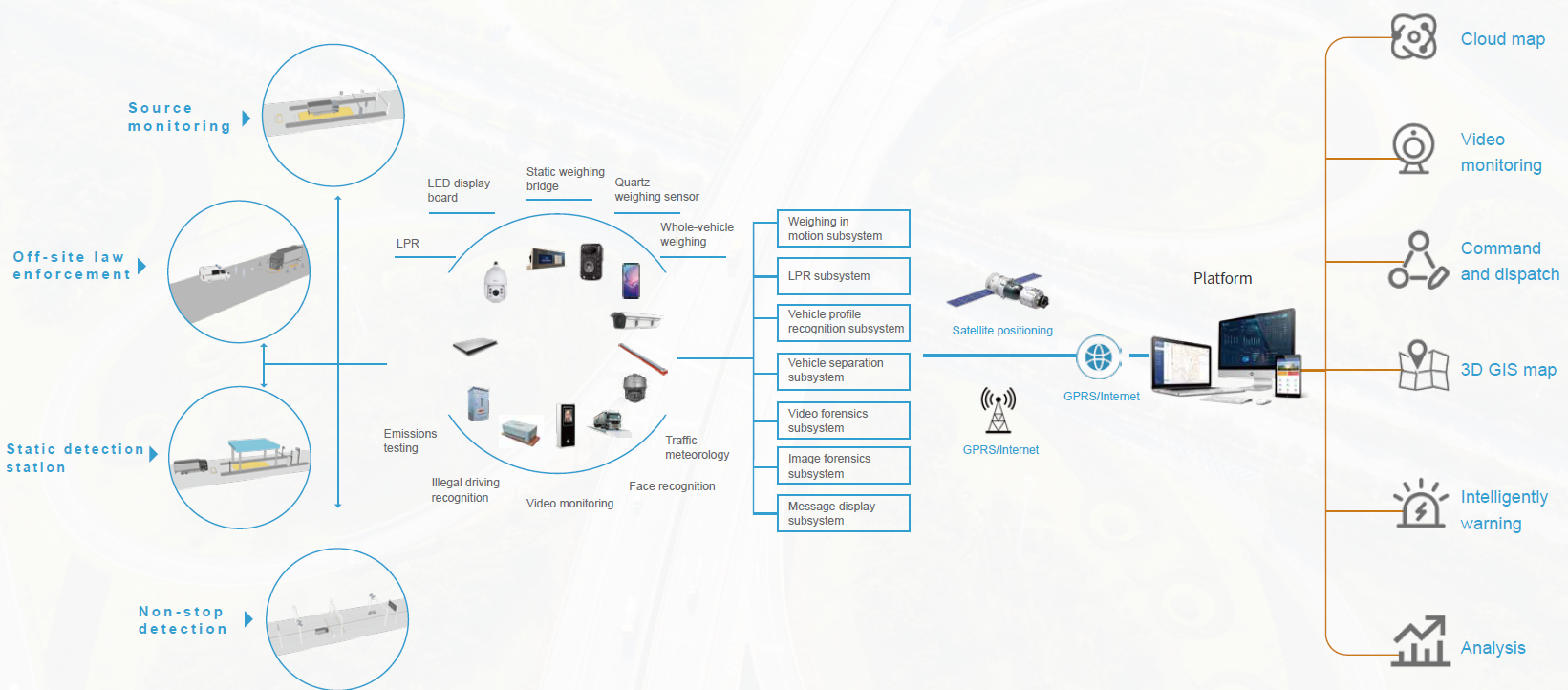

Enviko Quartz Dynamic Weighing System (Enviko WIM համակարգ) բարձր ճշգրտության դինամիկ կշռման համակարգ է, որը հիմնված է քվարցային սենսորների վրա, որը լայնորեն օգտագործվում է տրանսպորտի ոլորտում: Այս համակարգը օգտագործում է Enviko քվարցային սենսորները՝ իրական ժամանակում մեքենաների դինամիկ քաշը չափելու համար՝ դրանով իսկ հասնելով տրանսպորտային միջոցների բեռների ճշգրիտ մոնիտորինգի: Համակարգը բնութագրվում է բարձր ճշգրտությամբ, հուսալիությամբ և երկարակեցությամբ՝ արդյունավետորեն օգնելով ճանապարհային տրանսպորտի կառավարմանը և ճանապարհային ենթակառուցվածքների պահպանմանը:

Առավելությունները

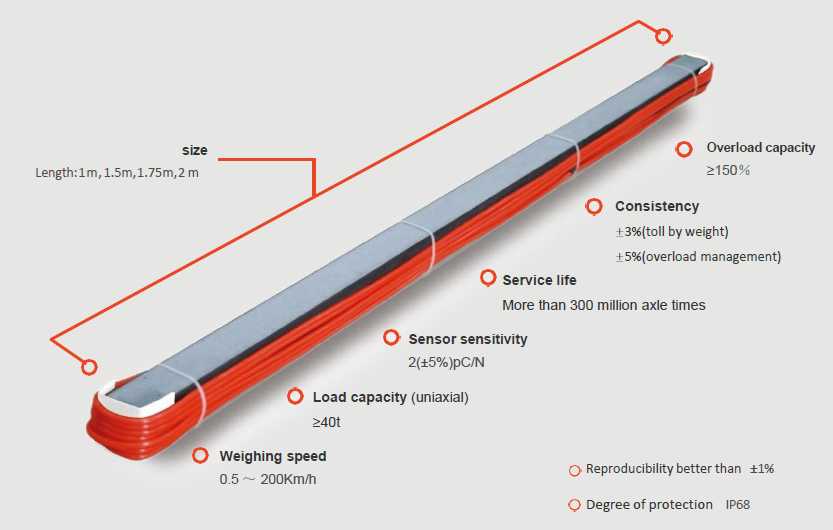

1.Բարձր ճշգրտությունEnviko Quartz Dynamic Weighting System-ում օգտագործվում են Enviko քվարցային սենսորներ, որոնք ունեն չափազանց բարձր զգայունություն և ճշգրտություն՝ հնարավորություն տալով ճշգրիտ չափել մեքենայի քաշը և իրական ժամանակում տվյալների փոխանցում:

2.ԵրկարակեցությունEnviko քվարցային սենսորները պատրաստված են բարձրորակ նյութերից՝ գերազանց մաշվածության և ճնշման դիմադրությամբ, ինչը երկարաժամկետ կայուն աշխատանք է ապահովում ճանապարհային կոշտ միջավայրում:

3.Հեշտ տեղադրումEnviko Quartz Dynamic Weighting System-ի տեղադրման գործընթացը համեմատաբար պարզ է: Տեղադրման կոնկրետ քայլերին հետևելով՝ համակարգը կարող է արդյունավետ կերպով տեղակայվել և կարգաբերվել:

4.Իրական ժամանակի մոնիտորինգՀամակարգը կարող է իրական ժամանակում վերահսկել մեքենայի քաշի տվյալները և փոխանցել տվյալները կենտրոնական կառավարման համակարգին անլար փոխանցման տեխնոլոգիայի միջոցով՝ հեշտացնելով տվյալների վերլուծությունը և կառավարման անձնակազմի կողմից որոշումների կայացումը:

5.ԲազմաֆունկցիոնալությունԲացի կշռումից, Enviko Quartz Dynamic Weighting System-ը նաև ունի տրանսպորտային միջոցների նույնականացում, ծանրաբեռնվածության ազդանշաններ և այլն՝ տրամադրելով համապարփակ լուծումներ երթևեկության կառավարման համար:

Տեղադրման քայլեր և մեթոդներ

Կայքի հետազոտության տեխնիկական պահանջներ

1.Կշռման տարածքի ընտրությունՀամոզվեք, որ կշռման տարածքը ուղիղ ճանապարհ է կշռման կայանից 200-400 մետր առաջ և հետո, առանց խաչմերուկների՝ ապահովելու մեքենայի համապատասխանությունը կշռման տարածքում և բարելավելու կշռման ճշգրտությունը:

2.LED էկրանի տեղադրումԽորհուրդ է տրվում տեղադրել լուսադիոդային դիսփլեյը 250-500 մետր կշռման վայրի ետևում՝ վարորդներին հեշտացնելու համար քաշի մասին տեղեկատվությունը դիտելու համար:

3.Խուսափեք կորերից և թեքություններիցՇինարարության համար ընտրեք ուղիղ ճանապարհային հատվածներ և խուսափեք կշռման համակարգը ոլորանների և թեքությունների վրա տեղադրելուց:

Սենսորների դասավորության տեխնիկական պահանջներ

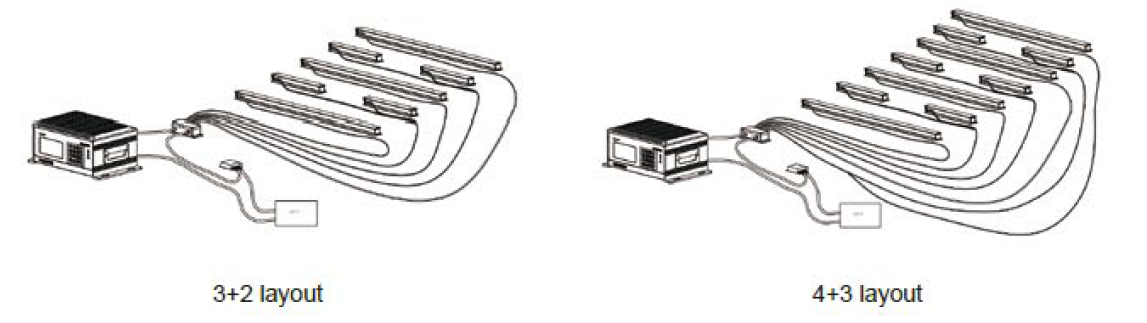

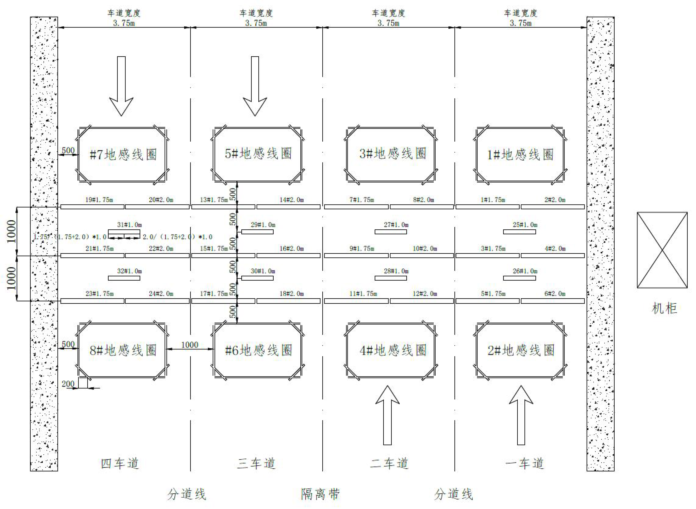

Enviko Quartz Dynamic Weighting System-ի սենսորներն ընդունում են «3+2» դասավորությունը՝ ամբողջությամբ դրված երեք տողերով և տվիչների յուրաքանչյուր շարքի միջև 1 մետր հեռավորությամբ: Երեք շարքերի մեջտեղում դրված է 1 մետր երկարությամբ սենսոր (4,25 մետրից ցածր մեկ գծի լայնության համար) կամ 1,5 մետր (4,25 մետրից բարձր մեկ գոտի լայնության համար): Սենսորների երկարությունը համամասնորեն բաշխված և հավասարեցված է ամբողջ շարքի սենսորների ծայրերին՝ 0,5 մետր հեռավորությամբ:

Ճանապարհի մակերեսի փոփոխություն

1.Շինարարական պայմաններԼրացրեք ճանապարհների փակման և երթևեկության շեղման աշխատանքները՝ ապահովելու շինարարական սարքավորումների և նյութերի պատրաստվածությունը:

2.Շինարարության գործընթաց:

·Չափում և նշումՉափել և նշել նախագծային գծագրերի համաձայն՝ շինարարության տարածքի ճշգրտությունն ապահովելու համար:

·Ճանապարհների կտրում և ճեղքումՕգտագործեք ճանապարհ կտրող մեքենա՝ 10 սմ-ից ավելի կտրման խորությամբ տարածքը կտրելու համար, այնուհետև կոտրեք ճանապարհի մակերեսը:

·Հիմնադրամի մաքրում և հարթեցումՄաքրեք հիմքի փոսը և հարթեցրեք այն՝ օգտագործելով հարթություն և թեոդոլիտ՝ հարթություն ապահովելու համար:

·Բետոնի թափումԼցնել բետոնը նախագծման պահանջներին համապատասխան՝ ապահովելով, որ բազային շերտի բետոնը լցվում է մեկ քայլով և կատարեք թրթռումային և մակերեսային մշակում:

·Ամրանների վերամշակումԴրեք և կապեք ամրանն ըստ նախագծային գծագրերի` ապահովելով ամրանների ցանցի ճշգրտությունն ու կայունությունը:

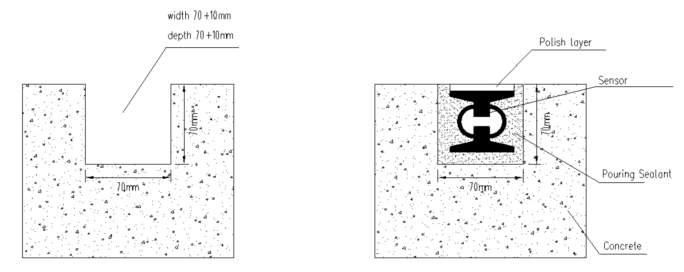

Սենսորների տեղադրման գործընթացը և տեխնիկական պահանջները

1.Սենսորի դիրքի հաստատումՀաստատեք Enviko քվարցային սենսորների տեղադրման դիրքը ըստ նախագծային գծագրերի և նշեք դրանք:

2.Սենսորների տեղադրում:

·Բազայի տեղադրումՏեղադրեք սենսորային հիմքը թափված բետոնե հիմքի վրա՝ համոզվելով, որ հիմքը հարթ է և ապահով:

·Սենսորների ամրագրումԱմրացրեք Enviko քվարցային սենսորները հիմքի վրա և կատարեք նախնական վրիպազերծում, որպեսզի ապահովեք սենսորների ճիշտ աշխատանքը:

3.Տվյալների մալուխի միացումՄիացրեք սենսորային տվյալների մալուխները և տեղադրեք մալուխները կենտրոնական կառավարման համակարգին՝ ապահովելով տվյալների կայուն փոխանցում:

4.Համակարգի վրիպազերծումԿատարեք ամբողջ համակարգի համապարփակ վրիպազերծում Enviko Quartz Dynamic Weighting System-ի բնականոն գործունեությունը ապահովելու համար:

Եզրակացություն

Enviko Quartz Dynamic Weighting System-ը (Enviko WIM համակարգ) իր բարձր ճշգրտությամբ, երկարակեցությամբ և բազմաֆունկցիոնալությամբ դառնում է ճանապարհային տրանսպորտի կառավարման կարևոր գործիք: Տեղադրման ձեռնարկում նշված քայլերին և մեթոդներին խստորեն հետևելով՝ կարելի է ապահովել համակարգի կայուն աշխատանքը և ճշգրիտ չափումները: Enviko քվարցային սենսորների աշխատանքը, որպես համակարգի հիմնական բաղադրիչ, ուղղակիորեն ազդում է համակարգի ճշգրտության և հուսալիության վրա: Հետևաբար, տեղադրման և օգտագործման ընթացքում շատ կարևոր է աշխատել տեխնիկական պահանջներին համապատասխան՝ Enviko Quartz Dynamic Weighting System (Enviko WIM համակարգ) առավելությունները լիովին օգտագործելու համար:

Enviko Technology Co., Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Չենդու գրասենյակ՝ Թիվ 2004, Բաժին 1, շենք 2, թիվ 158, Տյանֆու 4-րդ փողոց, բարձր տեխնոլոգիաների գոտի, Չենդու

Հոնկոնգի գրասենյակ՝ 8F, Cheung Wang շենք, 251 San Wui Street, Հոնկոնգ

Հրապարակման ժամանակը՝ օգ-07-2024